Wind turbine maintenance

The global focus on renewable energy means the wind turbine industry is growing rapidly. But how do you maintain wind turbines to ensure they function properly?

What does wind turbine maintenance involve?

Any wind turbine requires regular routine maintenance performed by professional wind turbine technicians to avoid component failures and unscheduled fault repairs.

Such planned maintenance is carried out once or twice a year and can take up to a day per wind turbine. The wind turbine technician will inspect all equipment to check if any repair is needed for the various components — these include air filters, the rotor shaft, yaw system, gearbox, electrical cabinet, and more.

Another important wind turbine maintenance task is to check and replenish oil and lubrication levels. Correct greasing is vital to lower failure probabilities, increase equipment lifetime and reduce operating costs.

All in all, planned maintenance performed by skilled wind turbine technicians is critical for any wind farm to avoid failure on components and drive down life cycle costs.

Why maintaining wind turbines is tricky

The several different types of equipment in a wind turbine mean it can be very difficult to amend component failures. Especially as the repair needs to be carried out in remote areas and spare parts for any equipment must be carried vertically several hundred feet.

Some components are relatively easy to repair or replace, but failures in the gearbox or around the wind turbine blades are very tricky to repair. Such failures usually entail significantly longer outage periods with unscheduled maintenance resulting in lost revenue.

Performing maintenance tasks is not for the faint-hearted

This makes the job of the wind turbine technician extremely important in any wind farm. These so-called grease monkeys probably have the most physically demanding job in the industry. To perform maintenance tasks they must climb up and down ladders with heavy equipment, spare parts, and grease containers in all weather conditions.

The emergence of ergonomic solutions, such as Easy Grease and the Hove Cartridge has made a huge difference in the technicians’ working environment. And with the new Hove Smart Lube, a wind turbine technician can also plan, track and document his work more easily.

Bigger wind turbines, bigger maintenance demands

Such solutions have become increasingly valuable, as both land-based and offshore wind farms are installing larger and larger wind turbines. This development places a heavy demand on performing correct turbine maintenance.

With the large components in modern wind turbines, component failure is a very cost-heavy occurrence with unscheduled stoppages and time-consuming repairs. By running preventative maintenance and ensuring correct lubrication levels based on accurate data, wind turbines can run at their highest capacity for years, driving down the operations’ maintenance costs.

Maintenance cost savings for wind farms

When you maintain wind turbines with Hove, you’re using the world’s most effective and efficient lubing solutions. Around the world, they help wind farm operations save a significant amount of time on turbine maintenance, keep turbines running for longer and avoid failure with accurate data.

Bearing

failures

Increasing

asset life

Savings on

maintenance

Hove solutions for wind farms

Since 2000 we have raised the bar in the wind farm industry, developing and producing ever more efficient and precise solutions for any maintenance team.

Hove Smart Lube

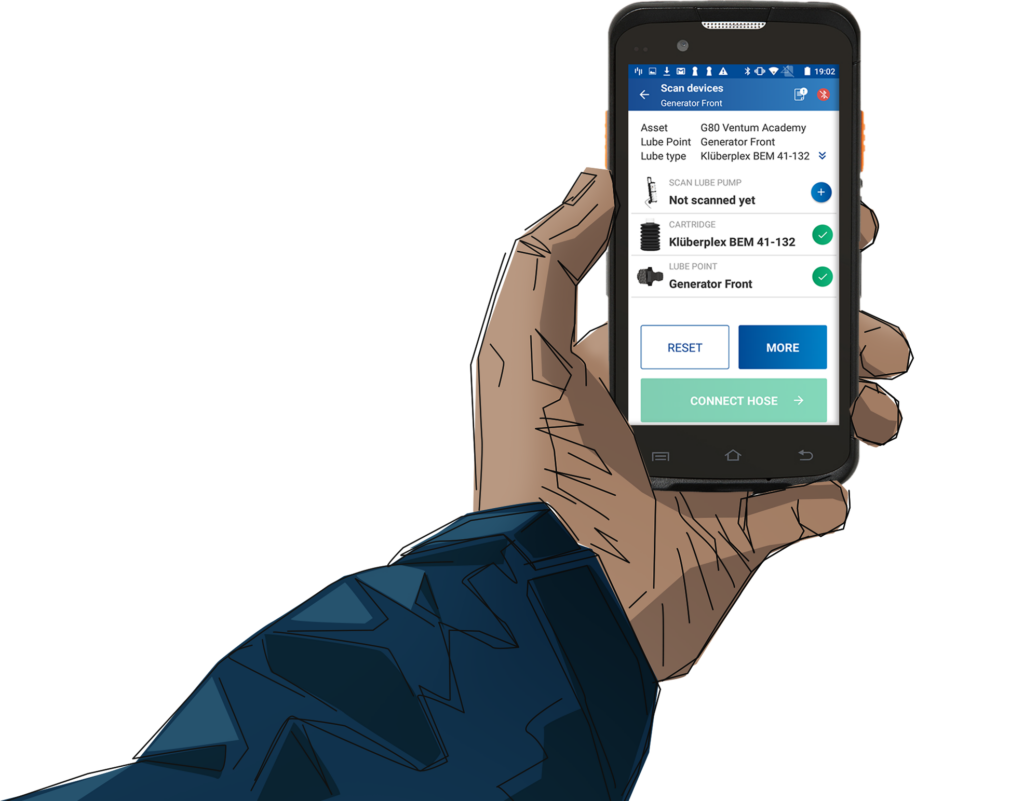

Hove smart is a wind turbine technology solution. It gives you real-time data to provide you with a detailed picture of each turbine in your operation. This helps you maintain full control of your preventative maintenance program.

EASY GREASE V5

Our new Easy Grease is a 48V IEC Class II lubrication pump. It adapts to various power sources and reduces the risk of airlocks. Its high pressure and flow make the pump suitable for direct lubrication systems.

Hove One

Semi-automatic pump for direct lubing of bearings. The compact design means Hove One is easy to carry up ladders and stairs and use inside turbines.

Hove Refiller v2

Fill up the reservoirs in central lubrication systems fast without risking contamination with this designated pump . The Hove Refiller V2 works with Hove cartridges.

Hove Easy Grease v4

The world’s leading greasing pump minimizes downtime with its ergonomic design and operational efficiency. It’s automated, safe, and extremely simple to use.

Hove pre-filled grease cartridges

Hove Cartridges are extremely simple to carry, mount and remove, greatly easing the wind technicians’ task. We supply cartridges in three different sizes with the grease of your choice. Each cartridge is filled in-house under strict control procedures to avoid any contamination.

Maintain smarter, maintain control

Hove Smart Lube is a field-proven digital solution. Plug it into your operations, get full traceability and maintain control of everything linked to lubrication.

Sign up for the Hove newsletter

Get insights and news on wind turbine maintenance. For wind farm owners, operators, servicing companies, and wind turbine technicians.

Wind turbine

maintenance FAQ

Wind turbine failures are hard to repair due to numerous reasons. The majority of turbines are located in remote locations, and workers face repairs up to 300 meters above ground.

Maintenance techniques for wind turbine equipment are typically preventative actions performed at a periodic interval according to manufacturers’ specifications.

Predictive maintenance uses data and AI to estimate the condition of wind turbine equipment and determine when maintenance is needed.

The physical movement of the blades puts a heavy toll on all other components inside the wind turbine. A failure can occur when components aren’t adequately maintained.

Failure of turbine components results in unplanned interruptions and costs in cranes and repairs, and revenue loss. A maintenance program helps prevent these incidents. The maintenance plan must be carefully designed to prevent unnecessary damage.

Get in Touch

If you have any questions about Hove products, quotes and services or would like to hear more about how Hove can benefit your business, please don’t hesitate to contact us. We are here to help.