Wind turbine lubrication

Global investments in wind energy is growing rapidly and the technology is under constant development. An often overlooked but crucial factor in achieving higher efficiency and more sustainability on wind power farms is ensuring correct lubrication of moving parts.

What does wind turbine lubrication involve?

A wind turbine has several mechanical bearings that allow the turbine to rotate and collect as much wind energy as possible. To ensure that the bearings run optimally and prolong their operative lifetime, they must be lubricated with specially developed wind turbine lubricants.

As downtime and repairs are costly affairs for wind farm operators, correct maintenance and lubrication play an essential role in maintaining a well-functioning and economically sound operation.

As the trend in the wind industry moves towards building larger and larger wind turbines, the costs of reparations and downtime grows accordingly.

Common misconceptions

Though the wind industry has made huge stride towards building more efficient turbines, and the market offers high-quality synthetic lubricants, the solutions and procedures used to lubricate wind power turbines are often less developed.

On several wind farms, turbines are lubricated by means of simple bucket pumps, and control of lubrication levels and intervals are not always formalized. In some cases, lubrication is performed by simply flooding each grease point. This increases the risk of human errors.

But the reliability of wind turbine equipment will suffer if it isn’t greased correctly and regularly. Nor is ‘over-greasing’ a preferable approach, as this is neither economically nor environmentally sound.

The use of bucket pumps and excessive amounts of lubrication also means wind turbine technicians need to carry very heavy loads on their backs when ascending wind turbine towers, often leading to injuries.

All in all, ensuring exact lubrication with the correct wind turbine lubricants represents a large economical upside for owners, investors, and operators in the wind energy industry.

On land or offshore – wind turbines can be tricky to lubricate correctly

The application of lubricants is a complex task for several reasons. The oil drain intervals depend on which component in the wind turbine gearbox need lubrication and the interval various according to the types of wind turbines.

Different wind turbines need a specific amount and type of grease depending on the components. All the grease points in every turbine must be replenished as specified by the manufacturer for the turbine to function properly.

To apply lubricant to the different components in the wind turbine gearboxes, the so-called grease monkeys must climb up and down ladders with grease containers and heavy equipment in all weather conditions. This makes their job the most physically demanding in the wind power industry.

Furthermore, wind farms are often located in remote areas or offshore making them difficult and time-consuming for technicians to reach and maintain. Repairing wind turbines in such locations are an even costlier endeavor.

Maintenance cost savings for wind farms

When you maintain wind turbines with Hove, you’re using the world’s most effective and efficient lubing solutions. Around the world, they help wind farm operations save a significant amount of time on turbine maintenance, keep turbines running for longer and avoid failure.

Bearing

failures

Increasing

asset life

Savings on

maintenance

Hove solutions for wind farms

Since 2000 we have raised the bar in the wind farm industry, developing and producing the world’s most advanced lubrication solutions for wind turbines.

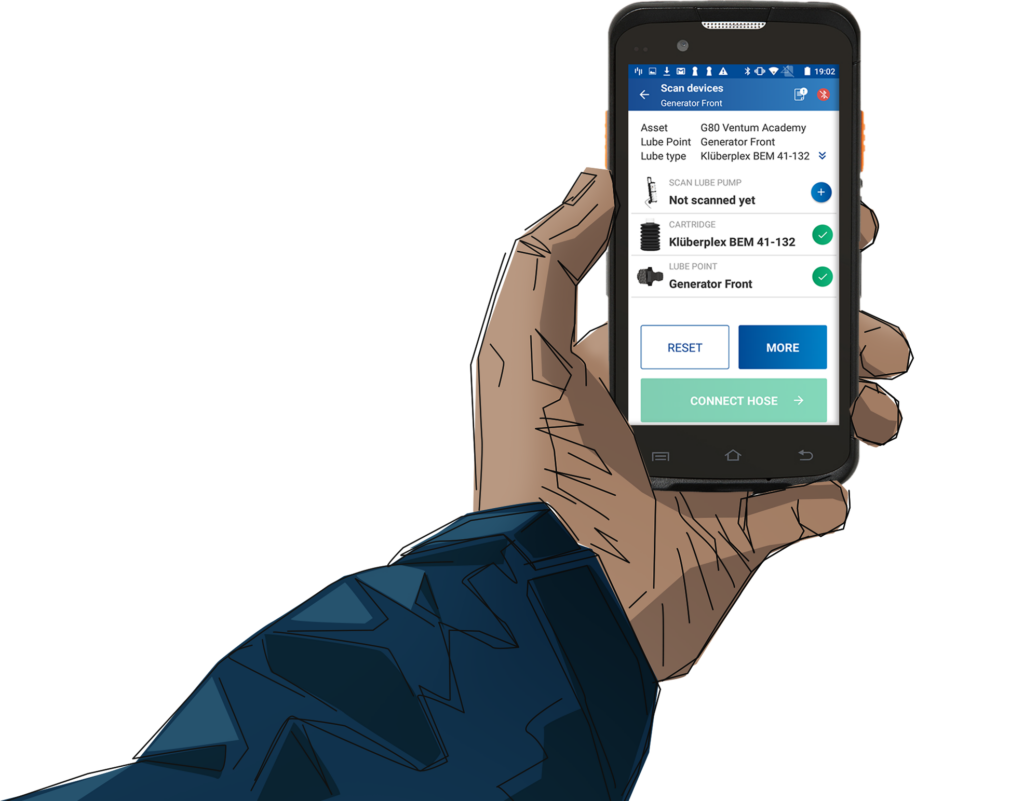

Hove Smart Lube

Hove smart lube is a field-proven digital solution that improves your lubrication maintenance. Plug it into your operations, get full traceability, and maintain control of everything linked to lubrication.

Hove Carry

Hove Carry is a portable lubrication pump for port cranes. With its compact design, battery-powered pump, and digital interface, it gives you full mobility and easy tracking and documentation.

Hove One

Hove ONE is a semi-automatic lubrication pump intended for direct lubrication of bearing. The small size and low weight make the machine a good choice for lubrication tasks in places with ladders and stairs.

Hove Refiller v2

The Hove Refiller is specifically designed to fast fill reservoirs on central lubrication systems without risking contamination. The solution uses Hove cartridges, which can be filled with the grease of your choice.

Hove Easy Grease v4

The world’s leading greasing pump minimizes downtime and has a dosing accuracy of +- 0.5%. The Easy Grease v4 can efficiently supply all greasing points. It’s automated, safe, and extremely simple to use.

Hove pre-filled grease cartridges

Hove Cartridges are extremely simple to carry, mount and remove, greatly easing the wind technicians’ task. We supply cartridges in three different sizes with the grease of your choice. Each cartridge is filled in-house under strict control procedures to avoid any contamination.

Maintain smarter, maintain control

Hove Smart Lube is a field-proven digital solution. Plug it into your operations, get full traceability and maintain control of everything linked to lubrication.

Sign up for the Hove newsletter

Get insights and news on wind turbine maintenance. For wind farm owners, operators, servicing companies, and wind turbine technicians.

Wind turbine

lubrication FAQ

The oil drain interval depends on the specific wind turbine and the different components inside the wind turbine gearboxes. With most wind turbines the lubricant typically last between 1-2 years, and more advanced synthetic lubricants can help extend the lifecycle even further.

The amount of lubricant for a wind turbine depend on the turbine design and the different components inside the gearbox.

The synthetic lubricants, that are used for maintenance of wind turbines, is usually polyalphaolefin-based and can be further subdivided into hydraulic oils, grease or gear oil.

The lubrication oil is placed into the wind turbine’s gearbox. The turbine lubrication system contains filters for the lubrication oil, and it is either pumped through the system or is gravity fed.

Get in Touch

If you have any questions about Hove products, quotes and services or would like to hear more about how Hove can benefit your business, please don’t hesitate to contact us. We are here to help.